The edge inspection vibration knife integrated machine is a device that integrates vibration knife cutting and automatic edge inspection functions, mainly used for processing edges of various materials. The processing mainly includes the following steps:

Firstly, place the materials to be processed on the workbench of the equipment, and then set the processing parameters such as cutting speed and cutting depth through the human-computer interaction interface.

Next, the device begins to automatically patrol the edges, detecting the edges of the material through laser or infrared sensors, and transmitting the detected edge information to the control system.

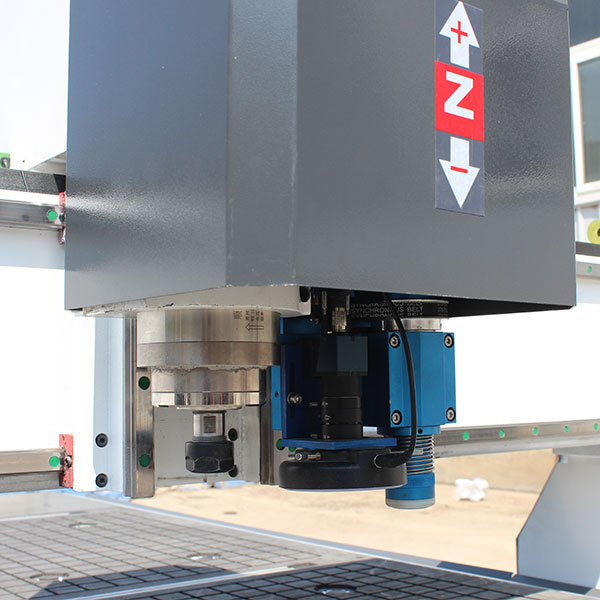

The control system controls the vibration knife to perform cutting based on the set parameters and edge information. The vibrating knife disperses the cutting force of the blade over a larger area through high-frequency vibration, thereby reducing the impact of cutting force on the material and improving cutting accuracy and efficiency.

During the cutting process, the equipment will automatically adjust the angle and position of the blade to ensure smooth cutting. At the same time, the device will also monitor the cutting process in real time through sensors. Once any abnormal situation is detected, the cutting will be immediately stopped and an alarm will be triggered.

The equipment will automatically stop cutting and take out the processed material from the workbench, completing the entire processing process.