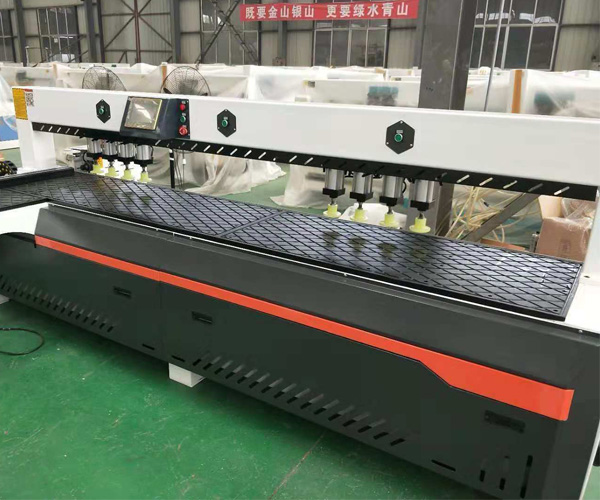

The installation process of the side hole machine is as follows:

1. Determine the placement of the machine and adjust its level.

2. Connect the electrical control cabinet to the power supply and check if all switch buttons are functioning properly.

3. Turn on the air compressor and adjust it to the appropriate pressure.

4. The installation of pneumatic pipelines should ensure that the pipeline interface is firm and not shaken. 5. Check the jet disk and cutting tool to ensure that they do not collide during operation. 6. Carefully read the instruction manual and assemble the accessories and workpiece fixtures according to the instructions (note: labor protection equipment must be worn during work). After completing the above steps, conduct a trial operation to verify whether the equipment can operate normally before starting to use the punching machine.. The precautions include not changing the original parameter values or functions arbitrarily; Overloading work is strictly prohibited; If any abnormal phenomenon occurs, the input power should be cut off in a timely manner and personnel should be notified for maintenance, etc. Overall, the details of different models may vary. It is recommended to check the website or consult relevant technical personnel for information.