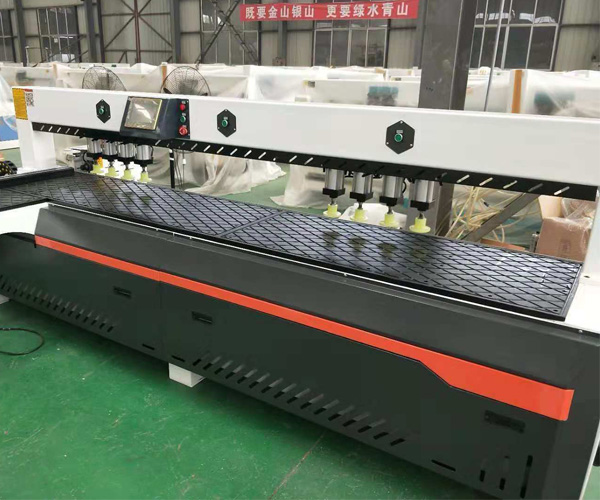

The manufacturing method of the side hole machine is as follows:

1. Prepare tools and materials, including laser markers, cutting machines (saws), tapping machines, and screws. Firstly, process the parts and label the dimensions accordingly; At the same time, it is necessary to design positioning blocks and stamping dies for matching use. Only by doing these preliminary works well can the overall production and manufacturing process of the equipment begin.

2. Choose the appropriate spindle speed based on the size of the drilled hole, and the quality of the product is also affected by the high or low air pressure (the normal air output is usually 5-8 kilograms per minute). When operating, it is necessary to follow the steps described in the instructions. When installing the template, it is necessary to ensure that the parallelism between the upper and lower sides does not exceed 0.1mm to ensure the service life and working accuracy of the mold. 3. For some special products, special fixtures or auxiliary tools are needed to complete the task and achieve unparalleled results. 4. Machine debugging is a crucial step. After completing a product, it must be checked for qualification and accepted by relevant personnel before it can be considered completed and stored. The above information is for reference only. Specific details can be consulted with individuals.