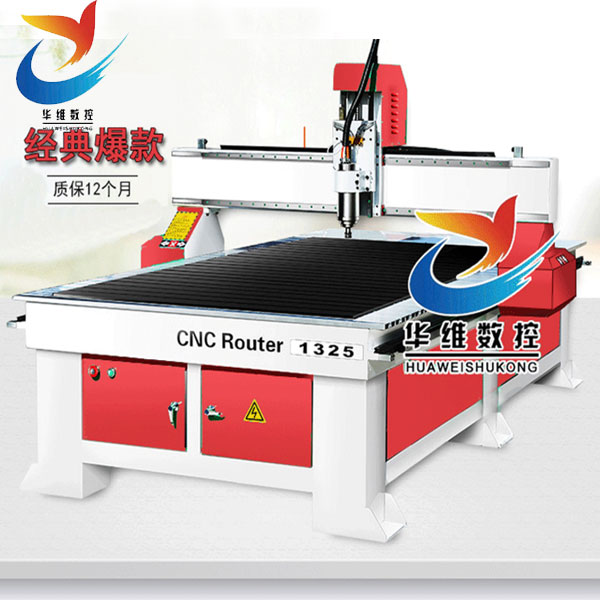

The processing process of advertising engraving machine includes the following steps:

1. Prepare materials: Use cut wood, boards, and metal sheets or PVC boards for printing, ensuring that all necessary tools and consumables are ready.

2. Set up the machine: Adjust and set up the drawing program on the computer to facilitate operation according to the design drawings.

3. Cutting: Place the product to be processed on the platform and secure it with suction cups or fixtures. Sawing or removal of excess materials according to design requirements.

4. Knife alignment and carving: Next, align the knives on each surface and input work instructions into the drive head. Subsequently, a continuous process of "carving" begins, during which it is necessary to pay attention to grasping the strength to adapt to the needs of different materials.

5. Post production editing: After the initial draft of the work is completed, it needs to be finely polished, repaired, and perfected through other post production processes. This step is to ensure that the details and quality of the work achieve the desired effect.

6. Inspection: After completion, carefully check whether the finished product meets expectations, whether there are any remaining traces or defects that have not been discovered and corrected in a timely manner. At this point, the entire production process of a beautiful advertising carving machine comes to an end.

Overall, this requires a deep understanding of the equipment and software, as well as foresight and proactive handling of various possible unexpected situations. This is why advertising engraving opportunities have evolved from simple woodworking machinery to the production of laser marking machines and spray lines.

- General instructions for pressurized drilling machine

- The function of vibration engraving machine

- Common knowledge of advertising engraving machine

- Introduction to Advertising Carving Machine

- How to customize a woodworking carving machine

- What should be noted for advertising engraving machines

- Introduction to the integrated machine of edge inspection vibration knife