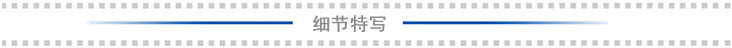

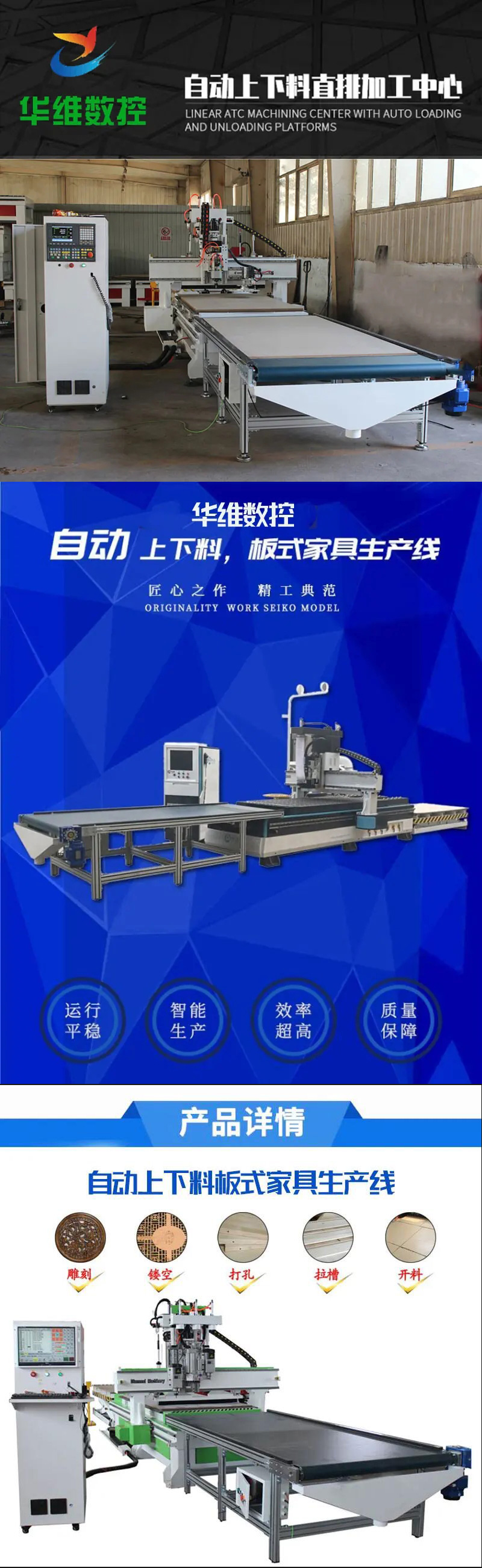

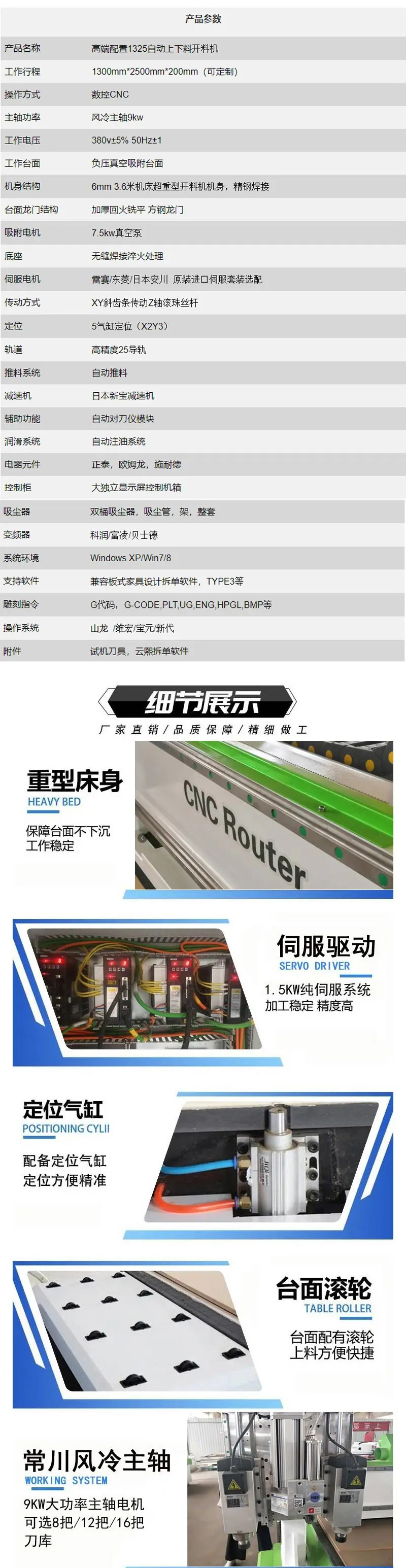

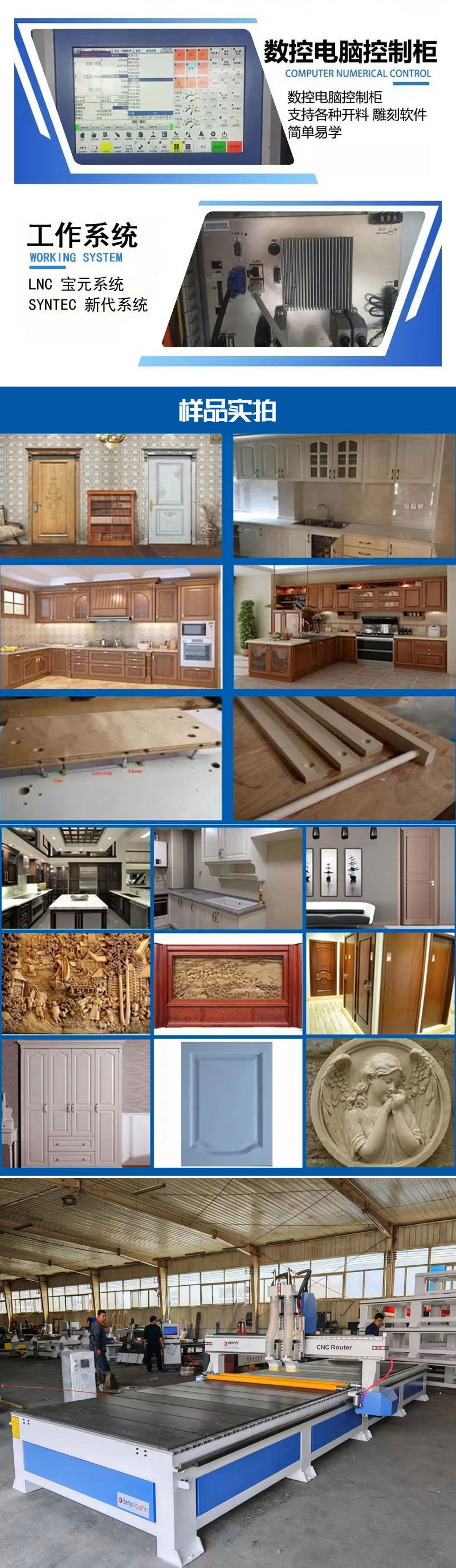

The advantages of Huawei CNC cutting machine compared to traditional cutting saw 1. With the increasing demand in the Chinese market, panel furniture has experienced explosive development in the past year. Huawei CNC cutting machines have overcome the disadvantages of traditional cutting saws, such as rigid operation, inability to cut irregular shapes, and rigid operation. Huawei CNC cutting machines can cut any irregular shape with only one person's operation, and the utilization rate of panels reaches 2.85 square meters. 2. Traditional cutting saws require two people to lift and adjust the size of the board back and forth, which can cause back pain and soreness due to material fatigue throughout the day. Additionally, the lack of a vacuum cleaner in the cutting machine can cause significant harm to the operator's body. 3. The fully automatic loading and unloading cutting machine produced by Huawei CNC, combined with the edge sealing rotary line, can be operated by only one person to complete cutting and edge sealing, greatly improving production efficiency and saving a lot of labor to reduce enterprise costs. 4. A regular cutting machine can cut about 120-150 square meters of sheet metal per day, while an automatic loading and unloading cutting machine can cut about 150-180 square meters. Especially in the custom panel furniture industry, the special-shaped products that used to give you a headache can now be easily solved. 5. Huawei cutting machine is a fully CNC foolproof operation, whether it is a regular cutting machine or an automatic loading and unloading machine, you only need to hire a female worker to easily handle it. 6. Huawei CNC cutting machine has asked you to draw and calculate the dimensions on the drawings. You only need to input the dimensions on the computer to complete the automatic optimization and layout of the board, and zero errors make you no longer worry about calculating the wrong dimensions and causing board waste. 7. Cutting machines can also carve reliefs and cut hollow areas. In addition to different configurations, cutting machines and carving machines have different structures. Cutting machines require fast speed, high precision, stable cutting performance over a long period of time, and cut boards without serrations, melamine does not break edges, smooth cutting surfaces without burrs, and cutting boards that are not easily broken. Huawei CNC cutting machines adopt reasonable configurations, unique design processes, board positioning functions, and electrically controlled vacuum adsorption to save time, effort, and time. Huawei CNC's commitment 1. We have over 10000 users using it; 2. We provide free on-site installation, training, debugging and other services until you start working normally, ensuring that you can independently process and produce; 3. We offer you a large number of carved design patterns for free, and from the date of purchase, you can enjoy free software upgrades for life; 4. From the date of purchase, you can attend various technical training sessions for free at our company; 5. In terms of after-sales service, if you have any difficulties using or the product cannot be used normally, we will provide a solution within 3 hours after receiving customer feedback. 6. Provide consumables at the lowest price (as agreed in the contract), charge for replacement parts at the cost price of products that have exceeded the warranty period, and reduce your various costs Product features:& nbsp; Easy to operate; The automatic typesetting software paired with the machine only requires inputting the size of the board to automatically optimize the typesetting and generate processing codes. Ordinary workers can easily start working after 3-5 hours of training, relying on skilled workers for enterprises. Time saving; Computer automatic typesetting is much more efficient than manual calculation, saving typesetting time. The machine is equipped with an automatic positioning cylinder, which eliminates the need for repeated positioning after feeding, saving feeding time. Vacuum adsorption table can fix small-sized boards, ensuring that the boards do not shift during processing, without the need for fixtures to fix them, saving clamping time; Save materials; The computer automatically optimizes the layout to maximize the utilization rate of the board. Labor saving measures; Previously, cutting equipment such as push table saws required two people to operate, with workers constantly rotating the board and adjusting the ruler, resulting in high work intensity. One person could operate multiple machines for the cutting machine, resulting in low work intensity and saving labor costs; Irregular cutting; The cutting machine adopts a milling cutter cutting method, which can cut any shape. At the same time, the automatic typesetting software can also optimize the typesetting of irregular shapes, making irregular cutting faster and more accurate. High cutting quality; The cutting of the board has no edge breakage and the size is precise, providing effective guarantee for later installation; Improve the working environment for workers; Professional vacuum design can remove 96% of dust during the processing, changing the working environment of traditional push table saws where dust is flying around. Applicable industries: panel, office furniture, wooden doors, cabinets, wardrobes, bedside tables, speakers, game cabinets, computer desks, etc Usage: The machine is equipped with automatic typesetting software, which can process orders from different customers simultaneously, producing finished products directly in the most material saving way and at the fastest speed. Workers only need to place the board on the automatic feeding workbench, and the machine will automatically pick up, position, cut, and drill vertical holes. After the processing is completed, the automatic feeding device pushes the sheet onto the conveyor belt and simultaneously vacuums it. At this time, only one person needs to pick it up at the feeding point. National Unified Sales Hotline: 400-6587-688 Jinan Huawei CNC Equipment Co., Ltd Address: No. 18-1 Tonghua Road, Jinan City, Shandong Province Postal Code: 250000 Phone: 0531-88620266 Fax: 0531-88276988 Mobile phone: 15853195586 E-mail: cncmachine@jnhwcnc.com

{1}

{2}

{3}

{4}

{5}

{6}

{7}

{8}

{9}

{10}

{11}

{12}

{13}

{14}

{15}

{16}

{17}

{18}

{19}

{20}

{21}

{22}{23}

{24}

{25}

{26}