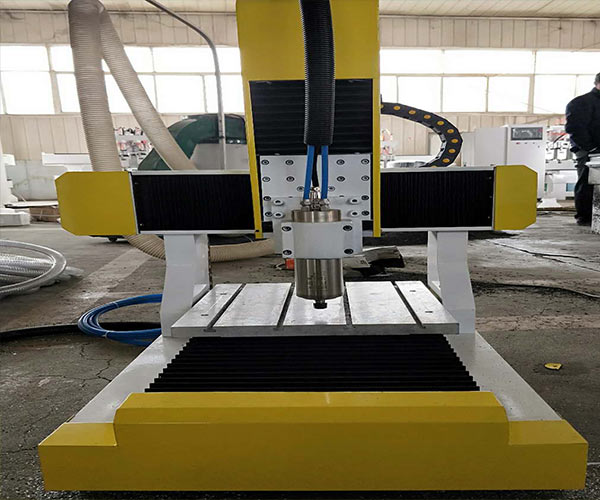

The installation process of the vibration engraving machine is as follows:

1. Preparation work. Choose a suitable location to place equipment and ensure a dry and dust-free environment; Check if the product accessories are complete, and promptly contact after-sales service for any missing parts. At the same time, clean up the dust and debris on the machine. These steps help ensure the normal operation and service life of the equipment.

2. Open box inspection and adjustment of fixed brackets. Confirm that all components are in place and carefully check the model and quantity before starting assembly. Reasonably select the support method (ground or air suspension) according to the usage location and adjust the levelness of the fixed base as required. This step requires careful operation to ensure stability and accuracy.

3. After all the above are ready, the power supply can be turned on to observe the current and sound situation to determine the forward and reverse rotation of the motor, and then gradually add various functional accessories to achieve the desired effect. This part involves electrical knowledge and must be carried out by personnel to avoid safety accidents. It is also necessary to keep good maintenance records. When completing the above process, attention should be paid to keeping the tools clean and maintaining the cleanliness of the site environment. The details of the work cannot be ignored, which will bring convenience and speed to future use. In summary, the word count for the entire process is approximately XXX words without exceeding the limit of 400 words, for your reference. (Note: This is for reference only and does not constitute a recommendation.) Please consult relevant personnel for more specific and accurate guidance during the actual implementation process..