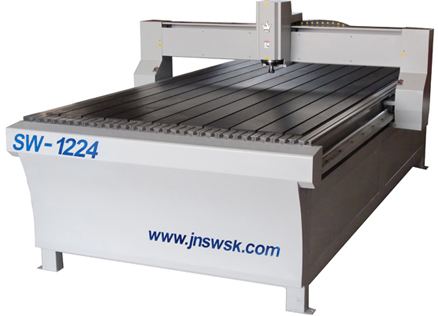

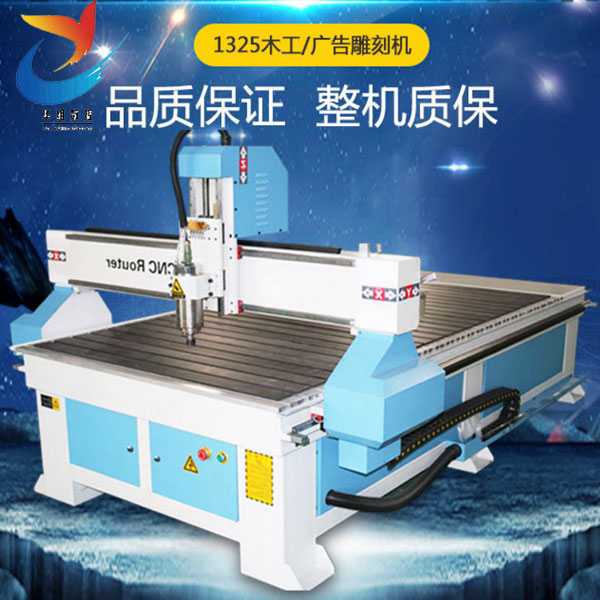

The following precautions should be taken when cleaning the advertising engraving machine:

1. Ensure that the device is turned off and disconnect all connected power sources.

2. Use a vacuum cleaner or brush to clean the work area and internal dust particles of the machine to avoid damage to the motor caused by dust. At the same time, keep all moving parts clean and dry. Prevent water stains or other impurities from entering these areas and causing short circuit faults. For some hard to reach areas, compressed air can be used for cleaning.

3. Regular oiling and lubrication of the transmission parts is also an important step. This helps to extend the lifespan of the machine and improve production efficiency. Especially important load-bearing components such as guide rails and screw rods should be regularly oiled and maintained.

Do not use chemical liquids of unknown or unknown properties for decontamination to prevent corrosion of the circuit board and mechanical metal parts; It is even more unacceptable to use strong solvents to remove stubborn ink residue from the character machine. Before carrying out any maintenance, the power output of the equipment must be turned off, otherwise it may cause harm or fire accidents. If it is necessary to replace blades or other vulnerable parts, be sure to follow the instructions for operation; If you are unsure how to disassemble or install, please contact the after-sales personnel. Improper operation may damage the equipment and your own safety. (Generally speaking, this process does not involve...). Overall, it is important to take protective measures to ensure one's own safety and avoid leaving debris to prevent future problems. It is also crucial to maintain regularly and cultivate a good working environment. In general, it is important to promptly remove waste and dust during use (especially paying attention to the working surface of the cutting tool), and to arrange cleaning and maintenance reasonably and correctly. This can effectively increase the service life of advertising engraving and milling machines and reduce costs! Attention should also be paid to whether its storage conditions meet the requirements! I hope the above information is helpful to you