/men/product_view.aspx?id=42&gp=151

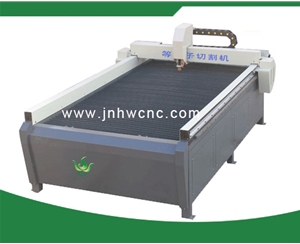

SW1325G Industrial Plasma Cutting Machine

call | parameter | Company(Unit) |

Processing area | 1300X2500mm | millimeter |

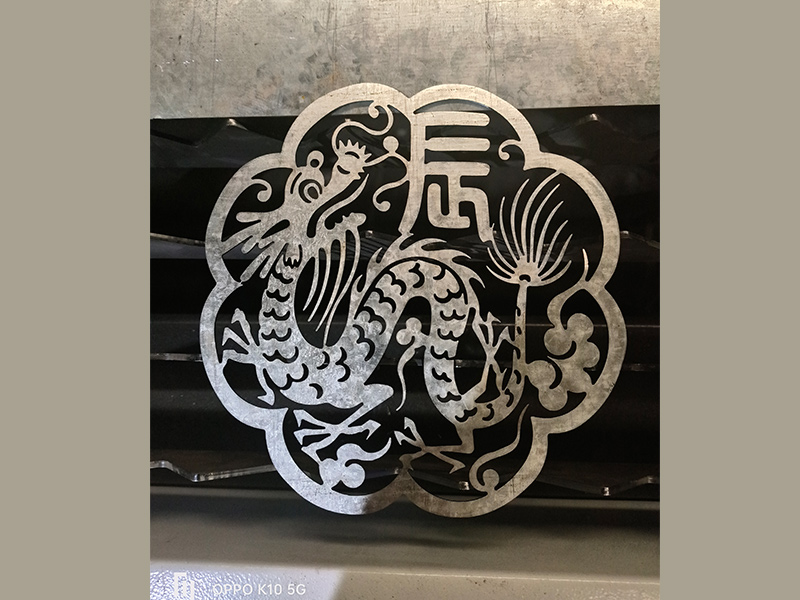

Processing materials | Iron plate, aluminum plate, galvanized plate, white steel plate, titanium plate | |

Processing thickness | 0.5-15 | millimeter |

Cutting speed | 0-8000 | Millimeters per minute |

power | eight point five | Kilowatt |

input voltage | 3-phase 380V | Fu |

Power frequency | fifty | hertz |

Plasma current | 60 or 100 | security |

File transfer method | USB interface | |

operation mode | Non contact arc ignition |

Thick walled square tube welded as a whole, artificial aging bed body, sturdy, non deformed, and with good rigidity.

Reasonable platform design, the tabletop is made of 10mm steel plate that has been precision machined and installed vertically on the bed surface. A precision machined cast iron rack cover is then installed on top to protect the vertical steel plate from damage under high-intensity flames. The flatness of the entire double-layer tabletop is maintained within 0-1.5mm.

A reasonable slope leakage design ensures that the processed workpieces and crushed materials slide down the slope to both sides of the cutter frame foot, which is safe and convenient.

The overall transmission adopts Panasonic servo motor configuration with Taiwan servo reducer and high-precision gear rack, ensuring low noise, smooth, and accurate coordinate movement performance.

Adopting the Sino US joint venture Starr control system and equipped with German automatic layout software that automatically saves materials.

◆ Adopting the American Flymat power supply (power 40A/120A/200A) and equipped with a high-sensitivity arc voltage regulator, the cutting distance is automatically adjusted to ensure the precision cutting of the workpiece.

Reasonable design and cutting of high-precision cleansing workpieces are the choice for cutting various thick and irregular plates.

Reasonable platform design, the tabletop is made of 10mm steel plate that has been precision machined and installed vertically on the bed surface. A precision machined cast iron rack cover is then installed on top to protect the vertical steel plate from damage under high-intensity flames. The flatness of the entire double-layer tabletop is maintained within 0-1.5mm.

A reasonable slope leakage design ensures that the processed workpieces and crushed materials slide down the slope to both sides of the cutter frame foot, which is safe and convenient.

The overall transmission adopts Panasonic servo motor configuration with Taiwan servo reducer and high-precision gear rack, ensuring low noise, smooth, and accurate coordinate movement performance.

Adopting the Sino US joint venture Starr control system and equipped with German automatic layout software that automatically saves materials.

◆ Adopting the American Flymat power supply (power 40A/120A/200A) and equipped with a high-sensitivity arc voltage regulator, the cutting distance is automatically adjusted to ensure the precision cutting of the workpiece.

Reasonable design and cutting of high-precision cleansing workpieces are the choice for cutting various thick and irregular plates.

Cutting of parts, cutting of thick plates with irregular shapes, and processing in the riveting and welding industry.

| National Unified Sales Hotline: 400-6587-688 |

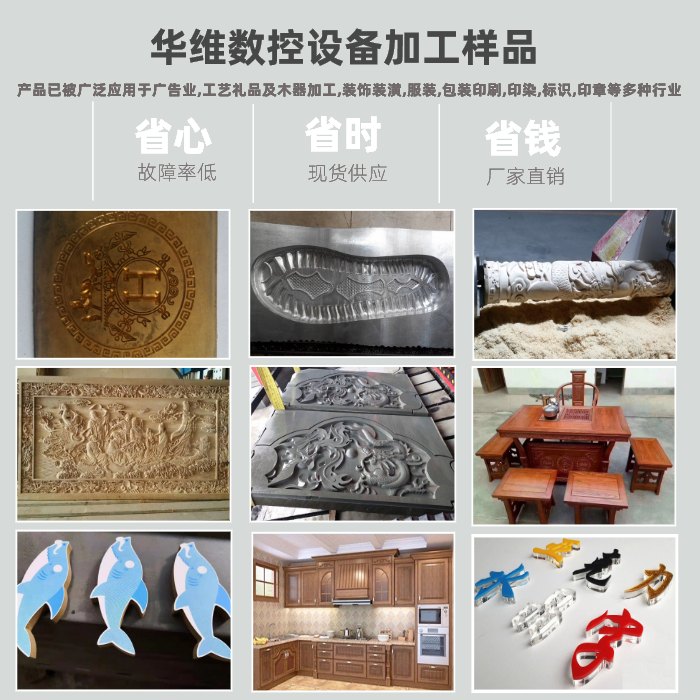

| Jinan Huawei CNC Equipment Co., Ltd |

| Address: No. 18-1 Tonghua Road, Jinan City, Shandong Province Postal Code: 250000 Phone: 0531-88620266 Fax: 0531-88276988 Mobile phone: 15853195586 E-mail: cncmachine@jnhwcnc.com |

Related products: