/men/product_view.aspx?id=40&gp=150

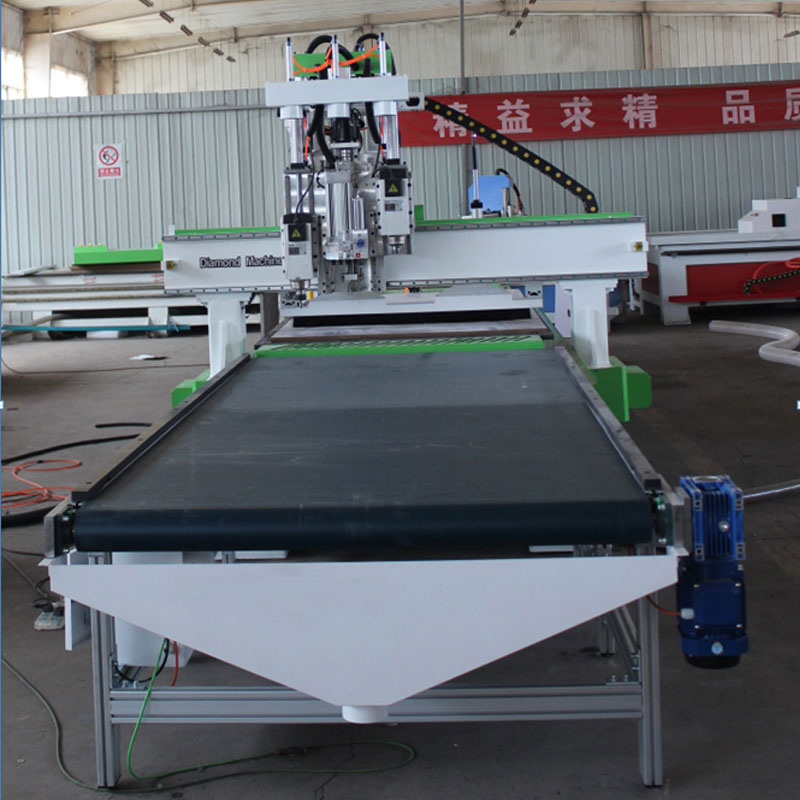

SW1118 Cylinder Carving Machine

oneThe bed and frame are welded with thick walled square tubes and undergo stress relief treatment. Good rigidity and no deformation.

twoThe Y-axis is driven by dual motors, with high-precision gear and rack transmission, high power, and smooth operation.

threeThe lifting platform adopts a 2KW three-phase synchronous motor, a turbine worm gearbox, which drives a large pitch sprocket and four large diameter trapezoidal lead screws, and is equipped with four large diameter guide light bars for smooth and reliable up and down movement. The maximum lifting weight can reach 1.5 tons.

fourThe rotator adopts a machine tool long disc (front and back claws) and a rear tail top pin. The rear top needle movement is guided by a square linear guide, with extremely precise concentricity. The chassis is made of ZL-102 integral casting and precision machining. The maximum diameter of the processed part can reach 400 millimeters, the length can reach 1200 millimeters, the weight of the processed part can reach 56 kilograms, and it is equipped with a workpiece balance roller.

fiveThere is a stainless steel sink on the lifting platform for processing stone, and an automatic water supply device is also installed.

sixTwo 4012 type rotators can be placed on the equipment platform. When cylindrical workpieces are not being processed, the rotators can be removed for flat carving. The thickness of flat workpieces can reach 700 millimeters

twoThe Y-axis is driven by dual motors, with high-precision gear and rack transmission, high power, and smooth operation.

threeThe lifting platform adopts a 2KW three-phase synchronous motor, a turbine worm gearbox, which drives a large pitch sprocket and four large diameter trapezoidal lead screws, and is equipped with four large diameter guide light bars for smooth and reliable up and down movement. The maximum lifting weight can reach 1.5 tons.

fourThe rotator adopts a machine tool long disc (front and back claws) and a rear tail top pin. The rear top needle movement is guided by a square linear guide, with extremely precise concentricity. The chassis is made of ZL-102 integral casting and precision machining. The maximum diameter of the processed part can reach 400 millimeters, the length can reach 1200 millimeters, the weight of the processed part can reach 56 kilograms, and it is equipped with a workpiece balance roller.

fiveThere is a stainless steel sink on the lifting platform for processing stone, and an automatic water supply device is also installed.

sixTwo 4012 type rotators can be placed on the equipment platform. When cylindrical workpieces are not being processed, the rotators can be removed for flat carving. The thickness of flat workpieces can reach 700 millimeters

In addition to the performance of other carving machines, this machine can be widely used for carving square and cylindrical shapes.

For example, carving and processing of cylinder handicrafts of hardwood, marble and White Marble.

| National Unified Sales Hotline: 400-6587-688 |

| Jinan Huawei CNC Equipment Co., Ltd |

| Address: No. 18-1 Tonghua Road, Jinan City, Shandong Province Postal Code: 250000 Phone: 0531-88620266 Fax: 0531-88276988 Mobile phone: 15853195586 E-mail: cncmachine@jnhwcnc.com |

Related products: