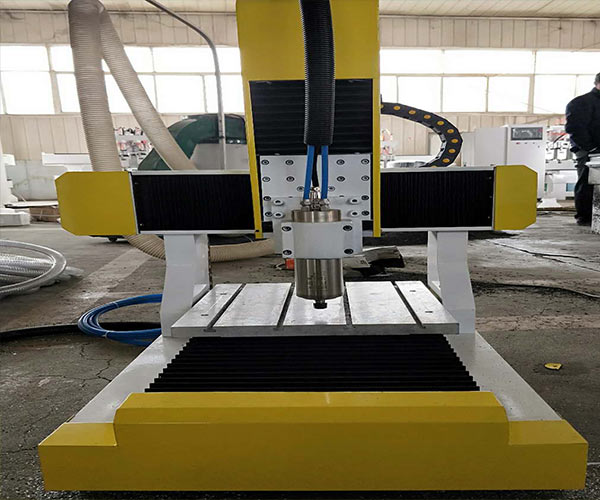

The steps for installing a vibration engraving machine are as follows:

1. Determine the location of the machine and ensure its accuracy. At the same time, sufficient space should be left for operation and maintenance purposes.

2. Conduct necessary inspections and tests, such as checking the appearance and structural condition, conducting performance tests, and testing electrical aspects such as grounding resistance, to confirm that the equipment is normal and without abnormalities before continuing with the next step of operation.

3. Check the list of unpacking accessories against the packing list one by one, and classify and organize the parts according to the configuration list. 4. Fix the host on the wooden board or bracket and lock the machine head with foot screws; Install the grinding wheel (pay attention to making the direction of rotation of the grinding wheel consistent with the direction indicated by the arrow on the machine body). 5. After connecting the power, use the key to select the "cutting" option before starting up the machine for processing (the new machine can be continuously operated for a period of time without error before being put into production). 6. Replace different saw blades according to different requirements and adjust corresponding parameters to ensure normal use. (Generally, the cutting depth is around 8MM) 7. Changing the rotation speed of the cutterhead (adjustable in both forward and reverse directions) and the feed rate to achieve the desired effect (the larger the F value, the stronger the thickening ability but the corresponding surface roughness decreases). In general, the above process can meet the needs of the vast majority of users. For some special application scenarios, adjustments and optimizations need to be made based on specific working environments and process characteristics. The above information is for reference only. Please refer to the books or consult the information obtained by the consultant.

The price of vibration machines varies depending on the model, ranging from over a thousand to over ten thousand. The most common price range is for mid-range products. Please refer to the relevant data!

- Mechanical parameters of side hole machine

- Applicable projects of vibration engraving machine

- Main advantages of laser cutting machine

- What is the process of installing and disassembling carving machine tools

- Comparison of the advantages and disadvantages of vacuum adsorption table surfaces in woodworking carving machines

- Maintenance instructions for side hole machine

- Introduction to vibration engraving machine